- Home

- About Us

- Products

- News

- Download

- Send Inquiry

- Contact Us

Web Menu

- Home

- About Us

- Products

- News

- Download

- Send Inquiry

- Contact Us

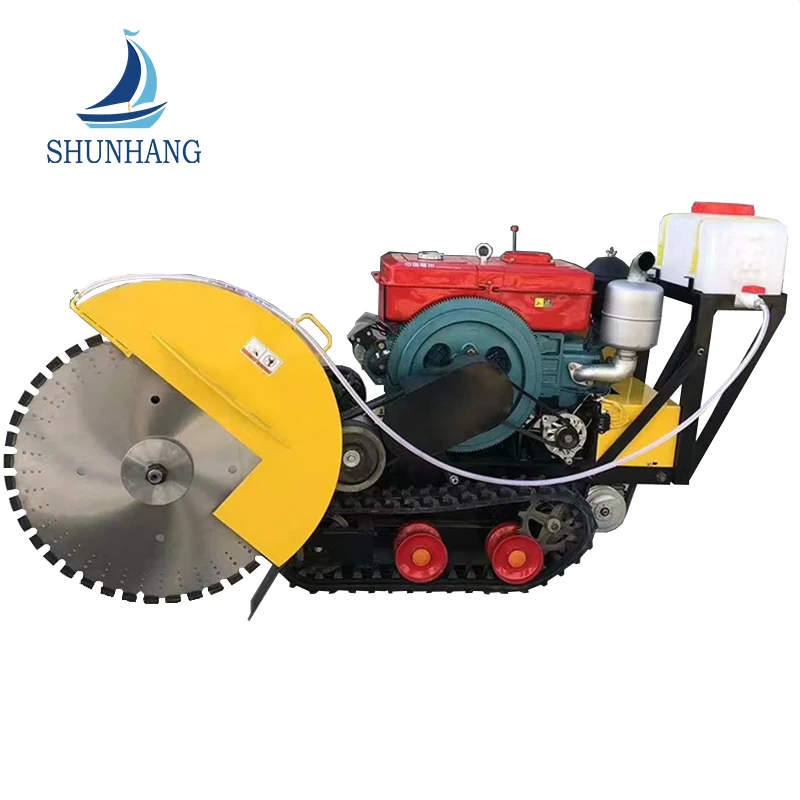

The road cutting machine, also known as concrete cutter machine, is a type of engineering machinery specifically designed for road construction and maintenance. Concrete cutter is mainly used for straight or curved cutting on asphalt, concrete and other road surfaces to complete road repair, expansion joint treatment, pipeline laying and other operations. As the core equipment of modern road engineering, the efficiency of the road cutting machine directly affects the construction progress and cost. Correct selection, standardized operation and regular maintenance can significantly enhance the safety and economy of operations.

In Shunhang industry, We mainly produce Gasoline Concrete Cutter, Diesel fuel Concrete Cutter and electric power concrete cutter. The main function is to cut seams on the road surface, creating a thin line with a depth ranging from 100mm to 200mm. Concrete cutter is often used on cement and asphalt roads. Operating the machine requires certain skilled personnel to carry out normal construction. The road cutting machine adopts a thickened frame and diamond saw blades. The concrete cutting machine is equipped with a water source to spray the cutting blades, which will extend the service life of the blades.

How to cut concrete by the concrete cutter?

1. Set the depth of the saw blade according to the thickness of the cement road, usually two-thirds of the thickness of the cement layer (for example, if the cement road is 15cm thick, the cutting depth is approximately 10cm).

If it is necessary to cut through thoroughly, it should be cut in layers and multiple times to avoid overloading the saw blade.

2. Before starting, make sure the saw blade does not touch the ground. Start the machine and let it idle for 10 to 20 seconds to confirm that it operates smoothly without abnormal vibration.

3. Slowly align the saw blade with the cutting line, lower it vertically, and maintain a constant speed of advancement. When wet cutting, the cooling water should be turned on simultaneously to reduce dust and cool the saw blade.

4. Hold the handles tightly with both hands and move forward at a constant speed along the marked lines to avoid deviation. Do not force a turn or retreat, as it may cause the saw blade to get stuck or break.